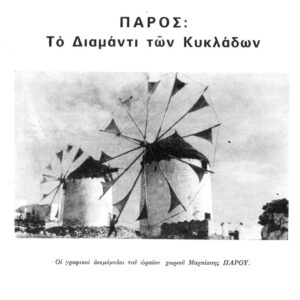

Windmills in Paros

The windmill in the Aegean

The windmill is “the most complex creation of a mechanism of widespread use of pre-industrial technology”, according to the architect and former President of the Institute of Greek Mills, Stephanos Nomikos. Especially on the islands, the use of windmills has been quite extensive for the grinding of grain, mainly barley and wheat, which have been the basis of the islanders’ diet for many years. However, they also had more uses such as the milling of fava beans in Santorini, oaks in Mykonos, sulfur in Milos, walnuts in Fourni and the tanning in Syros and Chios.

In the Aegean, the conditions facilitated the construction and operation of the mills: the wind was favorable with a frequency of over 310 days a year, the weather did not significantly damage the sails and the outer wooden parts of the windmill. The millers could also get millstones of exceptional quality from Milos.

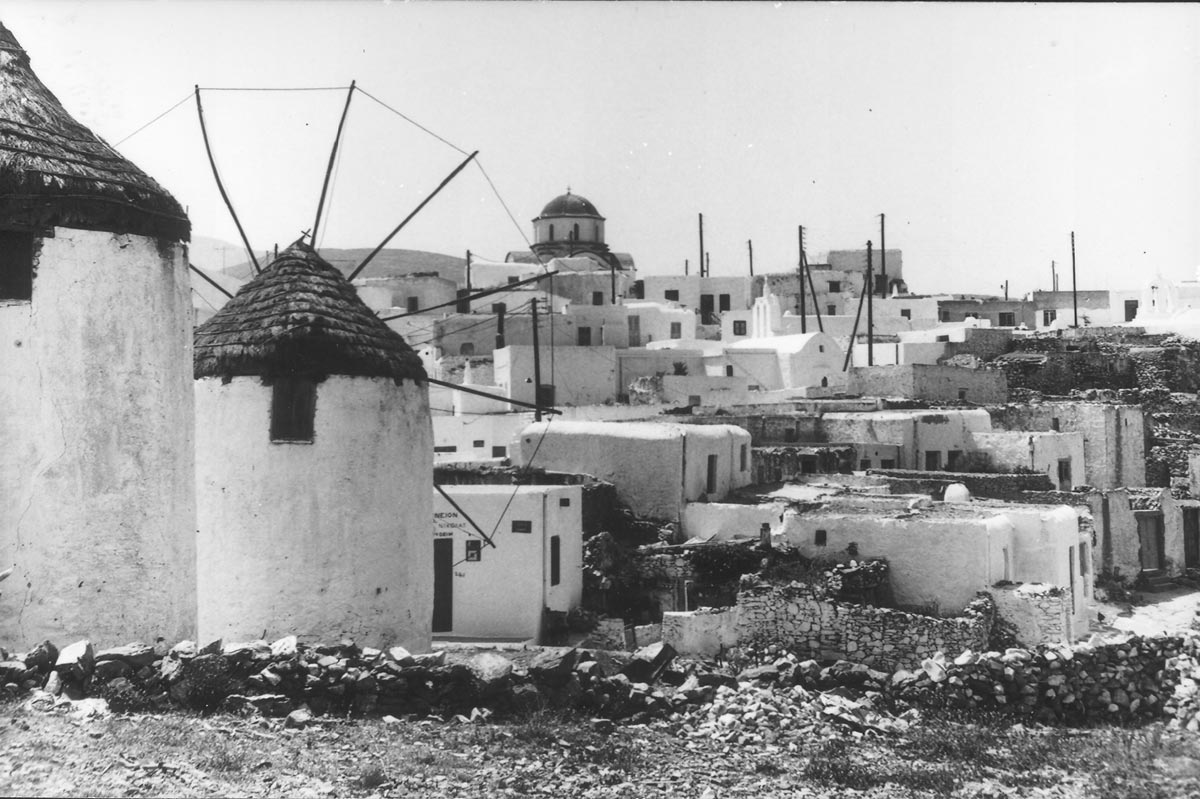

In Paros, according to the recent research of Yiorgos Beis, there were 55 windmills that ground grain, while it is estimated that there are more windmills in the Cyclades than anywhere else in Europe, both per square kilometer and per number of inhabitants.

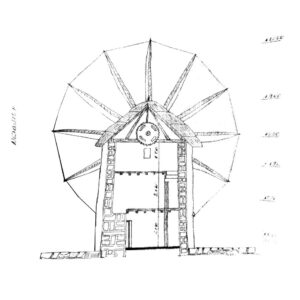

In Paros and the Aegean, we find the Mediterranean tower mill, with a proven history from at least the 13th century. It is made of stone with a conical roof made of wooden frame, reeds and grass cover that the miller repaired every year. Their architecture in the Cycladic islands was adapted to local techniques, both in terms of process and materials.

The construction of the windmill

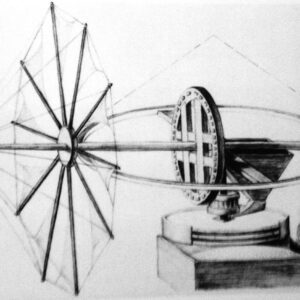

The windmill and its mechanism were a complex and expensive project, especially in the past. Their construction was undertaken by specialist millers with experience who knew the secrets of construction but also of the marking of the parts and the cutting of the wood, which were revealed only to their sons so that they would not have competition. More than 800 wages were needed to complete the building. The biggest difficulty was that the construction of the tower and the installation of the mechanism had to proceed in parallel, because the tower and the mechanism were interconnected.

On the top floor was the “axis” and the transmission system in the millstone, while on the lower floor was the grinding and storage of grain.

The circular shape of the floor plan derives from the need to rotate the axis according to the wind direction. With this given, the roof is necessarily circular defining the same shape for the whole building.

In order for the mill to be able to withstand the wind pressure, the masonry was thick on the bottom (0.9 cm-1 m), decreasing with height (0.6-0.7 m), thus creating the image of a windmill we are all familiar with.

The blades of the mills, the so-called “wings” had 10 or 12 “antennas”, with a length of 5-6 meters and tied sails. Depending on the direction of the wind, the miller adjusted the position of the rigging and the roof. Depending on the intensity of the wind, he opened and closed the sails.

Millstone from Milos

The construction of the rotating millstone is exceedingly interesting. It was 1 meter in diameter and 20 cm thick. It was made of small pumice stone and special rocks which are found mainly in the island of Milos. The millstone was assembled in Milos, where the individual parts were numbered, and subsequently it was dismantled for the transfer to Paros. Then, the assembly was done puzzle-wise in situ at the windmill site, by attaching the millstone onto two iron rings and through its middle hole traversed by the cogwheel (gear) which set the stone in rotational motion.

The miller had to adjust the distance between the two millstones, so that they would not rub against each other and not become gravel in the flour. The millstones wanted a different arrangement, depending on the type of grain, one for the wheat, another for the barley.

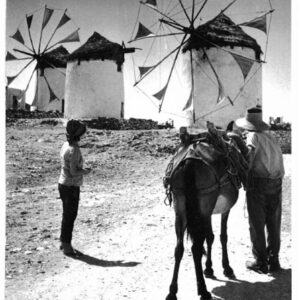

Clusters of windmills

An experienced mill joiner-carpenter was responsible for the selection of the place on the basis of the distance from the settlement to be served by the windmill and, of course, the soil morphology. Because the appropriate points were not many, we often find more than mills in the same place as in the case of Marpissa. The space, though, in front of each mill had to remain clear to ensure free wind flow. For this purpose, any construction of another windmill or any other buildings or even tree plantation were forbidden in order for the milling front to remain clear. Windmill construction influenced the street planning and alley layout of districts, given that the passage leading to them had to be large enough for the easy access of loaded animals.

The proud miller!

The miller’s job was lonely and arduous. His work was determined by the weather conditions and the needs of the inhabitants. He made sure that the millstones were clean and, as soon as the mill was ready, he unfolded one sail so that the villagers could come. His fee was usually 10% of the flour produced. A windmill could grind 20-70 pounds of grain per hour, about 70,000-80,000 kilos of wheat a year, depending on the intensity and direction of the wind.

The miller had to be fair, so that his fellow villagers would remain satisfied and strong so that he could move the roof and all the rigging against the wind, so that the air could be tamed. He was the master of the windmill, and many compared his role to that of the captain. He had to predict the weather, and always be prepared so as not to damage the windmill’s mechanism.

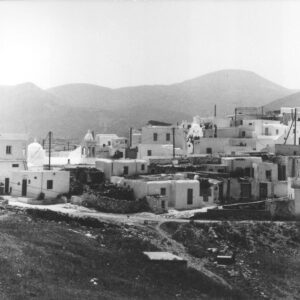

The mills of Marpissa

There were five windmills in Marpissa, Paros: a) Kaloudas’s heirs, b) Emmanuel Agouros, c) Stavros and Konstantinos Melanitis, d) Irene Perantinou, e) Ag. Gioka. According to the Government Gazette 527 / Β / 29-6-1989, they have been characterized as “historically preserved monuments because they are important samples of the “pre-industrial era”, and their rescue contributes to the preservation of the historical memory of the place”.

Near the provincial road from Prodromos to Marpissa and at the location “Piso Pigadi” was the windmill of Nikolaos Roussos or “Pentarakia”.

The Windmill of Agouros Family

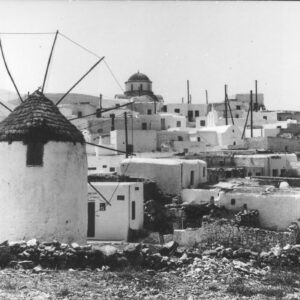

This windmill is the middle of three in a row windmills that dominate on the Mills site at the village of Marpissa, Paros. It is stone-built with a circular floor plan, with an area of 20 sq.m., 8 meters height and a wooden conical rooftop.

It belonged to the Agouros family from the beginning of the 19th century and stopped operating in the middle of the 20th. Four generations of millers passed through this windmill, from Demenegos Agouros to Yiorgos and his son, Manolis Agouros. The older ones remembered Barba-Yiorgakis who, during the hours of no wind, sat on the ground floor and wove baskets of reeds and wicker.

The descendants of the family with respect to tradition, history and the elements that characterize a windmill have made the restoration of the windmill. All the parts and tools of its interior that were used for its operation are preserved.

The windmill of Agouros family is a visiting site during the festival “Routes in Marpissa“.

"If windmills were ships, they would have travelled around the world many times."

The miller was a seaman of the land, since he struggled with the wind and often used nautical terms. When all the sails of the windmill were open, the mill was «Averta» meaning that it worked with all its mooring (remezza). The term «Remezza» derives from nautical life, which meant the free ropes with which they tied the boats in the harbor. At windmills, the word Remezzo meant the ropes with which they tied the sails of the windmill on the wire ropes of Antennas. When the sails of the windmill were not open, they were reefed.

Without strong remezza, the miller could not handle the windmill sails easily. In order to control the power of the windmill, the miller had to be careful all the time: to open and reef the sails according to the circumstances and the strength of the wind.

For the islanders, the work of the miller is more admirable than that of the captain because the miller flies the sails of the mill against the wind, while the captain always leads the ship in good weather.

Sources

Aliprantis, N. (1980), “Windmills and watermills of Paros”, Ta Pariana, A’, issue 2, p. 10, Athens.

Koroxenidou, Al. (1994), “The stone ghosts of the Aegean”, To Vima, July 31.

Marinakis, N. (2012), From the windmills of Paros to the museums of technology. Available at app.box.com [15/12/2020].

Nomikos, S. (2005), “The operation of water-powered and wind-powered installations in Greece”, Archeology and Arts, issue 97, December, pp. 39-47.

Speis, Υ. (2020) “Windmills in Greece”, issue 5, Autumn, pp. 13-23.

Ministry of Culture and Sports, Ephorate of Antiquities of the Cyclades, Turn mill blade.

Hellenic Mills Institute and Hellenic TIMS Team. Available at: hellenicmills.gr [15/12/2020].

Greekscapes. Available at: greekscapes.gr [15/12/2020].

We warmly thank the Agouros family for the information and valuable help.